Whatcom Waterway Remediation Project Removed Contaminated Sediment and Waterfront Structures to Allow for Mixed Use Access

Whatcom Waterway in Bellingham, Washington, has an extensive history of industrial use in the waterway and on the shoreline dating back to the mid-1900s. The Port of Bellingham owns the upland properties and is managing environmental cleanups in and around the waterway.

Phase 1 construction of the remediation was conducted between July 2015 and June 2016. American Construction Company was the prime contractor for dredging and land-based construction work. Anchor QEA, LLC did the remediation design, permitting, construction oversight and environmental monitoring; KPFF Consulting Engineers provided the structural engineering design and construction oversight, Strider Construction was American’s upland remediation sub-contractor, and the Washington State Department of Ecology (Ecology), the regulatory agency, which worked closely with the port and the engineers during planning and implementation of the cleanup.

The environmental cleanup process, including investigation and reporting, had been going on for approximately 15 to 20 years prior to Ecology’s decision to move into remedial design phase in 2010. Anchor QEA completed engineering design work for the project starting in 2011 with final design and project tender occurring in early 2015. Construction started in summer 2015 and in-water work was completed in March 2016; some additional upland closeout work was completed through summer 2016 and baseline monitoring was performed in fall 2016. Closeout reporting and Year 1 monitoring efforts were completed in 2017.

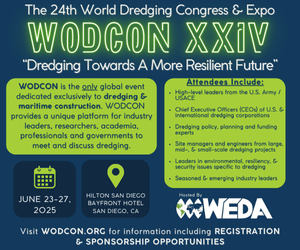

Anchor QEA submitted this project to the Western Dredging Association Environmental Committee under the Environmental Excellence Award category at the 2018 Dredging Summit & Expo.

Long-Term Cleanup Plan

The Whatcom Waterway remediation is an integral part of the port’s vision and includes helping develop waterfront dependent business, while providing for new commercial use, public use and recreational access, habitat creation, and connection to the Western Washington University campus.

Historic contamination in Whatcom Waterway is from industrial activities, including mercury discharges from a former chlor-alkali plant, wood waste and degradation products from past log rafting activities, and phenolic compounds from pulp mill wastewater discharges. Mercury was the primary contaminant of concern to inform the engineering design for remediation of the waterway.

The remediation was conducted by the port under a multi-phase Consent Decree that was negotiated with the Washington State Department of Ecology (Ecology). The Consent Decree includes a multi-phase approach for remediation of the entire cleanup site, and the primary objective of the Whatcom Waterway Phase 1 Cleanup Project was to address the risks to human health and the environment in the cleanup area.

General management goals for Phase I included reducing contaminant mass by dredging, capping contaminated sediment that could not be removed, maintaining the use of the waterway for local industry and recreational purposes, and improving shoreline conditions for public access and habitat creation.

Activities included dredging and landfill disposal of 111,450 cubic yards of contaminated sediment, placing approximately 800,000 square feet of engineered sediment caps, removing approximately 1,100 feet of treated timber bulkheads, removing more than 5,900 square feet o

f overwater treated timber structures, constructing a 765-foot containment wall to confine contaminated soils and groundwater, removing approximately 5,000 tons of concrete debris from the shoreline areas, excavating and landfill disposal of 6,600 cubic yards of contaminated shoreline soil, and replacing marine infrastructure (dolphins, fender piles, and floats) to restore operational use.

Dredging Contaminated Sediment

The engineering dredge design included removing the highest concentrations of contaminated sediment followed by capping.

The port is required (per tenant operational agreements) to maintain the navigable portions of Whatcom Waterway to elevation -18 feet mean lower low water (MLLW). Engineering studies identified contamination extending well below the limits that would allow for full removal of the contaminated materials, and the cleanup design was developed to achieve removal of the maximum amount of contamination practicable while meeting waterway operational use requirements.

The dredging design for the Inner Waterway remediation area included removing 120,000 cubic yards of contaminated sediment to elevation -24 feet MLLW in the navigable portions of the waterway and placing an engineered sediment cap over the underlying contaminated sediment to elevation -20 feet MLLW. The elevations for dredging and engineered sediment cap construction allowed for future maintenance dredging activities to -18 feet MLLW in the navigable portions of the waterway.

American Construction used two dredges on the project – the 500-ton DB Mukilteo for dredging contaminated material, and the 140-ton DB Palouse to place the capping material.

The Mukilteo was equipped with a 5.5-cubic-yard Cable Arm environmental clamshell bucket with an 11.5-foot by 12-foot footprint for most of the dredging work.

“The Cable Arm allowed us to dredge precise amounts with no overdredging. This is important when the cost to ship the material is high,” Rod Gowdy, project manager, said.

The barges were moved 75 miles south through Puget Sound to the Lafarge Transloading Facility on the Duwamish River in Seattle. Dredged material was offloaded, re-handled into rail cars and then transported via rail to the Columbia Ridge Landfill operated by Waste Management in Arlington, Oregon.

After dredging was complete, the DB Palouse, using a five cubic yard digging bucket, placed a cap consisting of 12 inches of sand covered by six inches of armor consisting of two-inch cobbles.

Capping material was obtained from a local source and brought to the site by truck, then loaded via conveyor onto material barges. Capping along the shoreline was accomplished using upland equipment, and all work was verified by hydrographic surveys.

For this project, American used WINOPS software for positioning and dredge management. Surveyor Chris Raymond used an Aut

odesk® Civil 3D® engineering design software to process volumes.

The port is responsible for maintaining water depth in the waterway and will conduct maintenance dredging in the future

Construction Sequencing

Construction sequencing was a critical element for the project schedule as in-water work was required to be completed in one construction season (August 2015 through March 2016) to meet project timeline and budget constraints.

Dredging and capping were sequenced to mitigate slope stability and structural considerations in the confined space of the waterway. The engineering designed specified dredging areas and sequencing requirements for all dredging to prevent recontamination of remediated areas adjacent to ongoing dredging activities and to minimize disruption of port tenant operations.

Onshore debris removal and soil excavation was managed on-site for re-use or off-site disposal at a local all-purpose landfill.

Upland remediation included dealing with contamination. Petroleum-impacted soils were discovered when removing a barge ramp structure, generating impacted construction water that could not be discharged to the waterway.

The contractor built a containment wall along the shoreline fronting the port’s Central Waterfront properties to contain the contaminated soil and water, which was leaching to groundwater, and sealed it so that the impacted groundwater could not flow into the waterway. The upland property is still going through cleanup process with Washington Department of Ecology. The groundwater is not being treated though it may be in future when the upland cleanup work is completed.

Dredging was completed after installing the containment wall, followed by placing the engineered sediment caps to stabilize the dredge slopes and containment wall structure.

The only active tenant in the Whatcom Waterway during the remediation was Colony Wharf boatyard, which performs small vessel lifts and launches and upland repair work and required consistent access to the waterway for the lift/launch of recreational vessels following completion of the remediation project. The port sequenced construction activities to allow the boatyard to continue operations with minimal impact and replaced the boatyard’s float and gangway system as part of the project.

The port is seeking tenants for other properties on the waterway and has redevelopment plans at the former GP Mill site.

Sustainable Approaches

The project involved implementing several sustainability approaches during the cleanup activities. The remediation work generated significant quantities of shoreline debris including large pieces of concrete from the building foundations of shoreline and upland structures. These large pieces of debris were removed from the shoreline and upland areas and brought to an upland stockpile area on port property where they were crushed and stored for beneficial use as structural fill during upland development for the former chlor-alkali mill upland area, instead of being disposed at an off-site landfill facility.

A large clarifier on the Inner Waterway shoreline included a pile-supported concrete foundation. The project required removal of the above-ground portion of the structure to allow removal of a shoreline bulkhead structure and regrading of the shoreline slope. The pile-supported foundation was left in place, and non-contaminated fill was placed in the foundation to help bring the upland area to grade after the clarifier was demolished. This sustainable approach reduced overall volume of demolition debris and allowed for beneficial re-use of excavated materials on-site as structural fill rather than removing the materials for off-site landfill disposal.