Dredge pumps are centrifugal pumps, driven by diesel or electric motors. The pumps work on the principle of centripetal force creating a pressure difference. Dredging operations are dependent on the reliability and suitability of the dredge pumps being deployed. Dredge pumps are often divided into low pressure, medium pressure and high pressure categories. They can be executed in single-walled or double-walled versions, and these can be either submersible or onboard dredge pumps.

Bas Rijkse, product manager at Royal IHC, which is headquartered in the Netherlands but works worldwide, said, “Pumps are a considerable investment for a dredging company, and the aim is to find an optimal balance between initial costs and total cost of ownership. In addition, consideration of the operation, the type of dredging, and safety are all determining factors in selecting the appropriate pump.”

A single vessel can be equipped with one, two or even three pumps that are used in series to boost dredging production or increase discharge distance. Double-walled high pressure pumps are typically used for discharge on trailing suction hopper dredges but also are used as booster pumps. Dredge pumps may be used on hopper dredges for trailing, pumping ashore or ‘rainbowing’ or on cutter suction dredges that have a single pump on the ladder or onboard.

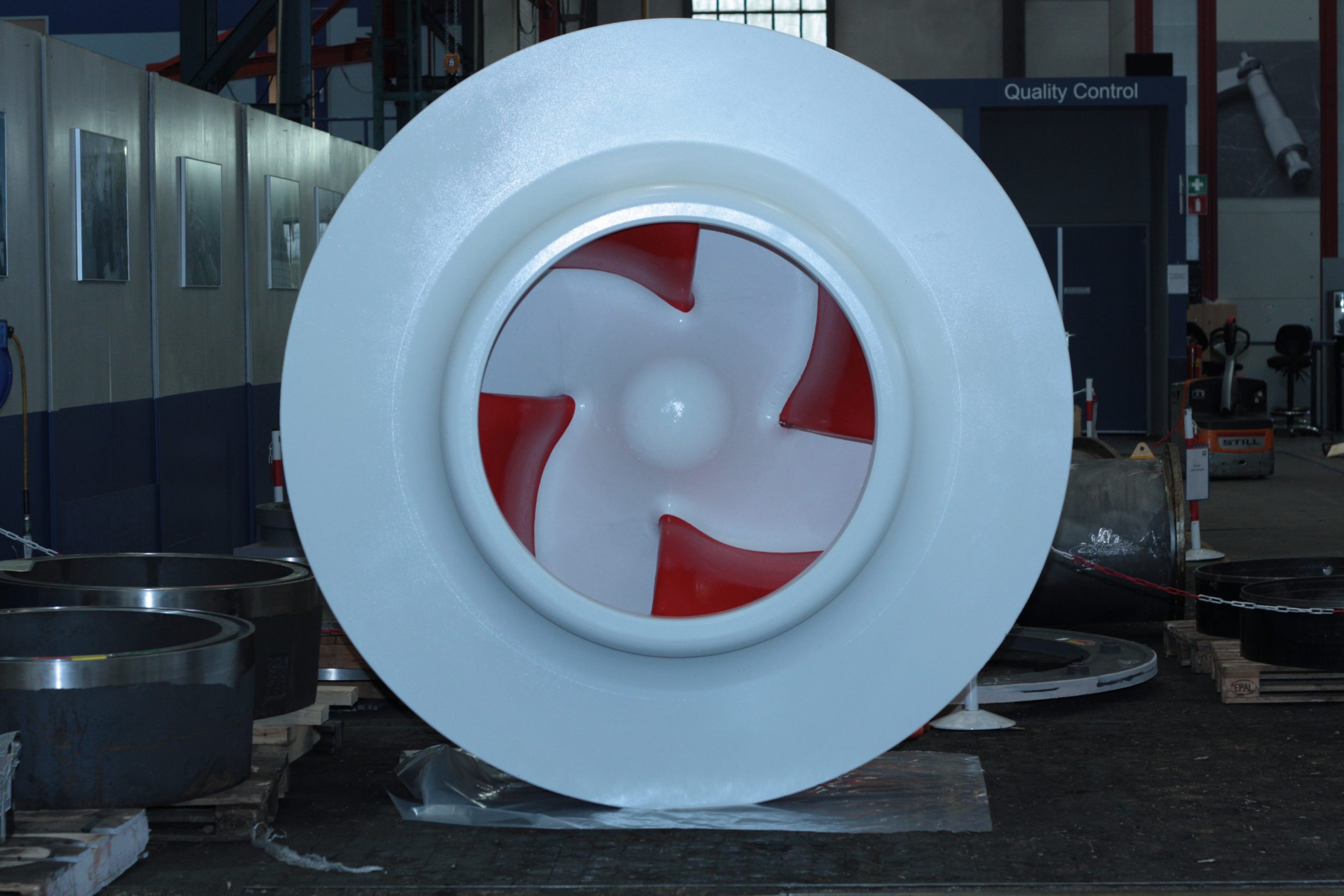

“With a long history of designing pumps, IHC combines the latest technical developments, computational fluid dynamics (CFD) and utilizes in-house testing facilities to create a full range of dredge pumps,” Rijkse said. “IHC is always looking for ways to improve its dredging equipment and to remain competitive. Curve® technology is an example of this. This is one of IHC’s latest innovations and represents a significant design improvement in the durability of its pumps distinguished by a new type of patented impeller blade.” The impeller is the rotating part of a centrifugal pump that moves the dredged fluids by rotation.

Gesine Bouter, IHC communication manager said, “Curve technology is an innovation on the pump’s impellers, in which the special curvature of the impeller blades provide for improved wear resistance and suction properties of the pump. This means that the lifespan of the pump is prolonged and production is increased.”

Curve technology is based on an algorithm, which streamlines the impeller to create optimum flow. The form of the blade was calculated theoretically and then the design was tested in the Royal IHC test facilities. Subsequently, its capabilities were confirmed by customers. The first generation of this curved impeller was introduced in 2014, but recently, in 2017 a new generation has been introduced. Royal IHC continuously improves the design of its dredge pumps in order to optimize efficiency, wear resistance and suction capabilities.

“There are of course many decision-making factors when choosing a pump and a variety of parameters that make the needs of each customer completely different,” Bouter said. Rijkse added, “When a client comes to us we make a total proposal for systems on the vessel – pipelines and pumps – the system has to work together with the dredge pump.”

Curve technology gives the client an extra value. As Rijkse describes it, the rotating impellers in a pump are subject to a great deal of wear and tear. Improving the wear resistance is important for a number of reasons: Better wear resistance means that the dredge does not have to stop operations and replace parts. This leads to more efficiency and improved production rates.

Rijkse said, “Our confidence in this Curve technology is such that nowadays our most popular dredges, the IHC Beaver® cutter suction dredge and the IHC Beagle® trailing suction dredge, are delivered with this curved impeller as a standard feature. The new curved impeller can also be retrofitted on all our pumps.”

Is this option more costly? The answer is yes. But according to both Rijkse and Bouter, the long-term benefits are high and the dredging companies that are using it now are reporting it to be cost-efficient.