A British firm, Haven Dredging, is touting a new towable dredging device that promises “cleaner, cheaper” dredging that “works with nature” by using tidal currents to disperse sediment near the channel, thus reducing the need to move and place dredged material.

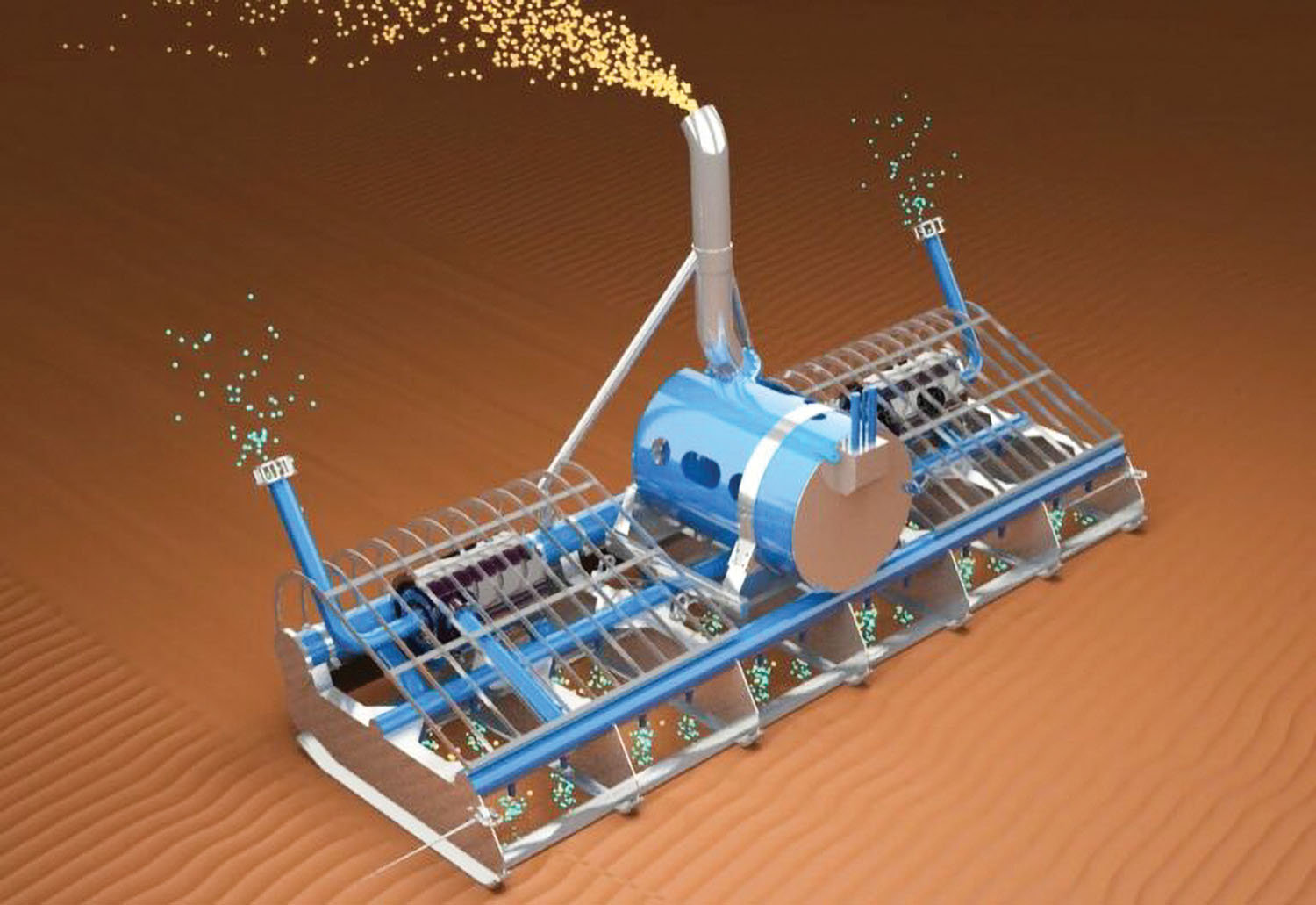

Tiamat, as the system has been dubbed, consists of a frame carrying two pumps. (The name comes from a Mesopotamian sea goddess, also represented as a dragon.) One pump is used to inject water into the sediment overlying the bed of the harbor, while the second pump extracts the diluted silt and pumps it up a 6-meter-tall pipe, from where it is released into the water column. The silt is then washed out of the harbor through the natural tidal currents – thus, “Dredging with Nature.”

The frame is mounted on the winch of a small work boat and lowered into the water to the required depth. The system can be used on standard small vessels that do not have to be adapted or modified. This flexibility “resolves some of the capacity and resource constraints that can exist in the dredging market,” according to Haven.

Tiamat does not rely on creating a density current; instead it uses the power of the tide and currents of the sea and rivers. Tiamat “promotes self-replenishment in the estuarian system, through the natural re-suspension of sediment.” Tiamat does not use side-casting, but rather places the sediment back into the water column at the appropriate depth.

Four trials of the Tiamat system were conducted by the Harwich Haven Authority, including an independent environmental impact assessment conducted by Royal Haskoning and HR Wallingford and reviewed by the Environmental Agency and Natural England of the U.K. After each trial and discussion of the monitoring, results and the impressions of the vessel crew, improvements were made to the machine and to working practice. Tiamat is now being used as part of Harwich Haven’s dredging processes. The company claims there has been no evidence of turbidity or the water quality being affected.

Haven says the “scalable” technology ensures a custom-designed solution for each port–maximizing the effectiveness of dredging. “Ports often complain that dredging plant is not available when needed in particular WIDs [water-injected dredging vessels],” the company said in a press release. “It is relatively easy to manufacture a Tiamat device, and with short lead times, while it could be over a year to take delivery of a new WID. “The use of Tiamat reduces the environmental impacts of dredging, through lower emissions and disposal of silt. Tiamat’s greenhouse gas emissions are about 70 percent lower than those of a comparable [trailing suction hopper dredge].”

Another possible advantage, the company said, is that Tiamat can, depending on the location, “help the maintenance and replenishment of mudflats and thereby reduce the requirement to undertake beneficial placement work.” Tiamat “sustainably dredges from the seabed or riverbed using a non-invasive method and encourag[es] the natural movement of the sediment back into water column.” Tiamat supports the ecology of mud flats, as it replaces the need for invasive “beneficial placement” of sediment, potentially disrupting wildlife settled there. Wildlife in or around the dredging zone will also be less affected because Tiamat shortens the dredging disposal process, encouraging the sediment to disperse naturally and more sustainably, rather than locating it somewhere else.

Caption for photo: Tiamat towable dredging device.