The Tennessee Valley Authority (TVA), a public entity charged with power generation in the Tennessee River Valley, has put a new Tier 4 towboat into service, marking a first for both a government agency and the shipyard that built it.

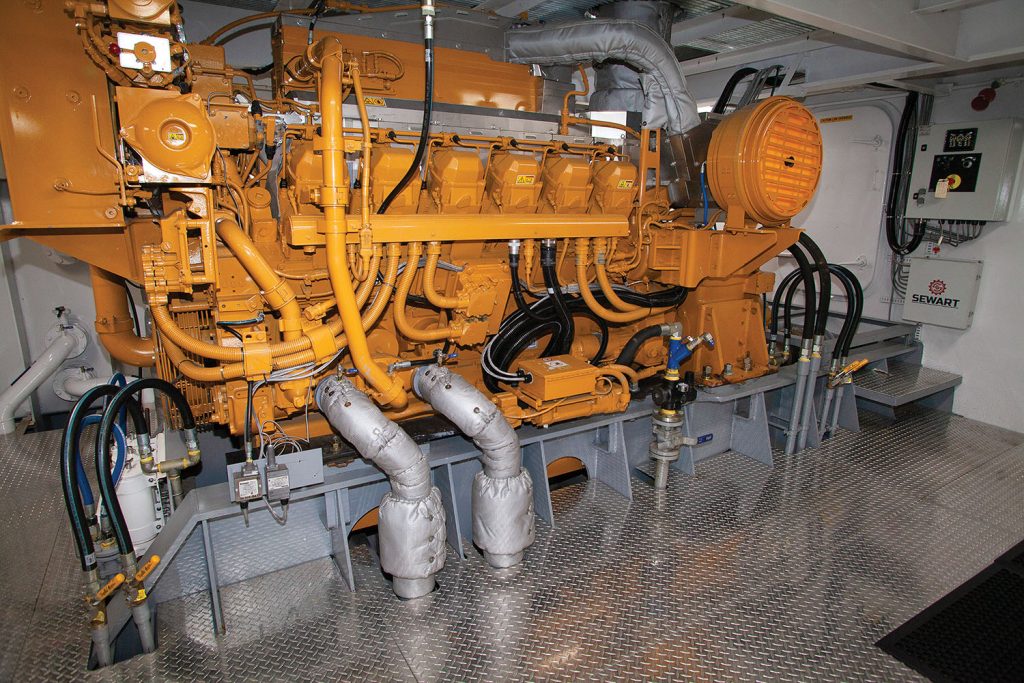

Port Arthur, Texas-based Vessel Repair delivered the mv. Freedom, a 100- by 34-foot towboat with a molded depth of 10 feet 9 inches and a draft of 9.5 feet, to TVA June 29. The Sterling Marine-designed towboat is powered by a pair of Caterpillar 3512E Tier 4 engines from Thompson CAT that each produce 1,341 hp. Those main engines, which are paired to Twin Disc MGX5600 gears from Sewart Supply, turn five-blade Sound propellers that have a 58-inch pitch and an 85-inch diameter.

Shane Carman, TVA’s manager of river services and coal combustion products, facility management, said he and his team first started exploring the possibility of building a new flagship towboat for the authority back in 2020.

“We reached out to a couple different architects to figure out how to go about doing this,” Carman said. “Before this, TVA hadn’t built a line-haul boat since 1979, so this was new territory for us. We wanted to make sure we did it right.”

To help identify what TVA wanted in a new towboat, Carman said he and his colleagues toured a number of towboats already in service, including some working for the U.S. Army Corps of Engineers, Golding Barge Line and Cooper Marine & Timberlands.

From there, TVA worked with Fairhope, Ala.-based Sterling Marine to design the new towboat.

Initially, the plan was for the mv. Freedom to be a triple-screw Tier 3 vessel. However, as the TVA team considered the agency’s identity as a power producer that already uses scrubbers in fossil fuel-driven plants to reduce emissions as much as possible, going with Tier 4 engines in the towboat made perfect sense.

“We want to be very good stewards of the environment, so we decided that if we’re going to do this, let’s go all in and do the same thing with the engine package on this towboat,” Carman said. “That’s when we transitioned from a triple-screw to a twin-screw Tier 4.”

Besides being the first Tier 4 towboat for a government agency, the mv. Freedom joins just a handful of Tier 4-powered towboats on the inland waterways. Still, Richard Tremayne, marine business manager for Thompson CAT, said that with the majority of Tier 3 towboat projects already in service, it won’t be long before Tier 4 is the default for new towboats.

“There are fewer and fewer Tier 3 large horsepower engines left in the U.S.,” Tremayne said.

While the mv. Freedom was Thompson CAT’s second Tier 4 towboat, it was the company’s 20th overall Tier 4 vessel, Tremayne said, including some triple-screw harbor tugs.

For a towboat, where engineroom space is at a premium, carving out room for the selective catalytic reduction system (SCR), which injects diesel exhaust fluid into the exhaust stream to reduce emissions, has been a task.

“Because it is a big box, one of the biggest challenges when this hit the market was where to put this thing,” Tremayne said. “I’ve seen some architects raise the house by a few inches.”

The Vessel Repair team proposed a different approach: placing the SCR box in the exhaust stack.

“Just like everything, you learn from paper to actually standing in front of it,” Vessel Repair’s Kurt Moerbe said. “Where the SCRs were originally placed made sense on paper, but when we got in there, we realized the extra space we had in the stack and how [the scrubbers were] taking the space in the upper engineroom.”

The shipyard, TVA, Sterling Marine and Thompson CAT team put their heads together and opted to instead locate the SCRs in the stacks.

“We mounted it to the stack opening, so if you need to get to the SCR, you can pull the stack off, and it’s in a place where the SCR can just be unbolted and pulled,” Moerbe said. “It’s a lot easier than if it would’ve been pressed against the forward engineroom bulkhead under deck plate. The engineroom cleaned up tremendously.”

Speaking of placing the scrubbers in the stacks, David Carver with Sterling Marine said, “It just makes sense.” In fact, he said Sterling’s next Tier 4 towboat project was laid out like that from the start.

Carver said Sterling Marine has been working with Vessel Repair on new builds for six or seven years.

“They’ve proven themselves time and time again,” he said. “If there’s a way to improve it, they’re going to do their best to make it a reality. They really push me. The shipyard is really the place where a project becomes a success or not.”

And the Tier 4 main engines aren’t the only feature of the mv. Freedom that’s noteworthy and environmentally conscious. TVA was determined to build a towboat free of any risk of spill or vapor release on deck. Therefore, on the mv. Freedom, there are no fill points or vents on the exterior of the vessel.

“We built internal compartments on both sides,” Carman said. “We have a full-size door you open, and all those components are on the inside. We hook up all those nozzles internally. That way, nothing can be spilled on the outside of the boat.”

In addition, all the deck equipment, including the vessel’s crane, winches and capstan, are electric, powered by the Freedom’s Caterpillar C4.4 99 kW generators, also from Thompson CAT.

Besides the environmentally focused components, the mv. Freedom also features five single-occupancy staterooms, each with its own dedicated full bathroom. There’s a lounge on the Texas deck with a convertible couch and its own full bathroom.

The mv. Freedom has tankage for 20,300 gallons of freshwater, 7,200 gallons of gray water, 4,500 gallons of potable water, 600 gallons each of gear and lube oils, 325 gallons of hydraulic oil, 25,500 gallons of fuel and 2,750 gallons of diesel exhaust fluid.

Shafts are by R.C. Schmidt & Sons, seals are by Simplan, and bearings are Thordon Rivertough. Fernstrum supplied the keel coolers, and Rio Marine supplied the engine alarms and steering system.

Wheelhouse Electronics provided the electronics and communication equipment, while Hiller supplied the fire safety equipment. Fendering is by Schuyler. Coatings are by PPG.

Besides its other deck equipment, the mv. Freedom also features two 1,000-watt Carlisle and Finch hybrid spotlights and an air horn from Kahlenberg.

The new mv. Freedom replaces an older towboat, also called Freedom, which TVA bought from the Corps of Engineers in 2007. As with the prior towboat, the new mv. Freedom will primarily serve TVA’s three nuclear power plants.

“We have a lot of components that are just too big to move over the highway, like turbines and generators,” Carman said. “We have our own refurbishment shop in Muscle Shoals, Ala.”

TVA has a roll-on/roll-off barge, which transports those components to and from the nuclear power plants.

“When we go through a plant outage and we’re going to replace a component, if the new component is in Muscle Shoals, we’ll load the new component and haul it to one of our nuclear plants,” Carman explained, “then take the old component back to Muscle Shoals for refurbishment.”

TVA’s towboat crews function a little differently than with a typical commercial towing company, Carman said.

“We don’t have any standard crew that works on any one boat,” he said. “We have four pilots, four deckhands, a mechanic, and they could be on any boat at any time.”

The mv. Freedom departed Vessel Repair and traveled the Gulf Intracoastal Waterway to Mobile, Ala., where it then motored up the Tennessee-Tombigbee Waterway. The boat then followed the Tennessee River to Muscle Shoals, its homeport.

Vessel Repair reports it has multiple orders for additional Tier 4 towboats already in place.

Caption for top photo: The Tennessee Valley Authority’s 2,682 hp. mv. Freedom is the first Tier 4 towboat owned by a government agency and the first Tier 4 built by Vessel Repair. (Photo courtesy of TVA)