While COVID-19 proved the dominant newsmaker for much of 2020, a steady stream of dredging and waterway announcements during the year will, hopefully, have a much more enduring—and endearing—impact on the maritime industry.

The waterway deepening news started early in the year, with the U.S. Army Corps of Engineers’ 2020 work plan, released February 10. The work plan, remarkably, included both funding for the first phase of deepening the Mississippi River from Baton Rouge, La., to the Gulf of Mexico to 50 feet and more than $274 million to fully fund the construction of the Mobile Harbor channel deepening project in Alabama, which will also bring that channel to 50 feet.

The Mobile Engineer District’s commander, Col. Sebastien Joly, and John Driscoll, CEO of the Alabama State Port Authority, signed the project partnership agreement for the Mobile Harbor deepening in June. The following month, Louisiana Gov. John Bel Edwards; Renee Lapeyrolerie, multimodal commissioner for the state; Maj. Gen. Dianna Holland, commander of the Corps’ Mississippi Valley Division; and Col. Stephen Murphy, commander of the New Orleans Engineer District, gathered at the New Orleans District’s headquarters to sign the partnership agreement for the Mississippi River deepening.

Funding for those two projects, which are now underway, totals more than $600 million. That, along with projects planned or progressing at the Houston Ship Channel and the Corpus Christi Ship Channel, will mean years’ worth of channel-deepening work for Gulf Coast ports, along with routine operations and maintenance.

Concurrent with the channel deepening announcements in 2020, states along the Gulf Coast also rolled out hundreds of millions of dollars in coastal restoration projects last year.

Those long-term investments in the nation’s waterways and coastal regions have led to historic investment in the future of the U.S. dredge fleet, said Bill Hanson, vice president of government relations for Great Lakes Dredge & Dock Company.

“With improved investments in ports, waterways and coastal projects, our clients can gear up their staffs and programs,” Hanson said. “We benefit from a more structured and well-funded approach in that we can better understand where the market is headed and make the appropriate investments in new equipment.”

Hanson noted that 10 new dredges have entered the U.S. fleet over the past five years, with at least five more under construction.

“This will likely continue as long as the Corps and state folks can help make their programs more predictable and consistent,” he said.

New Dredges

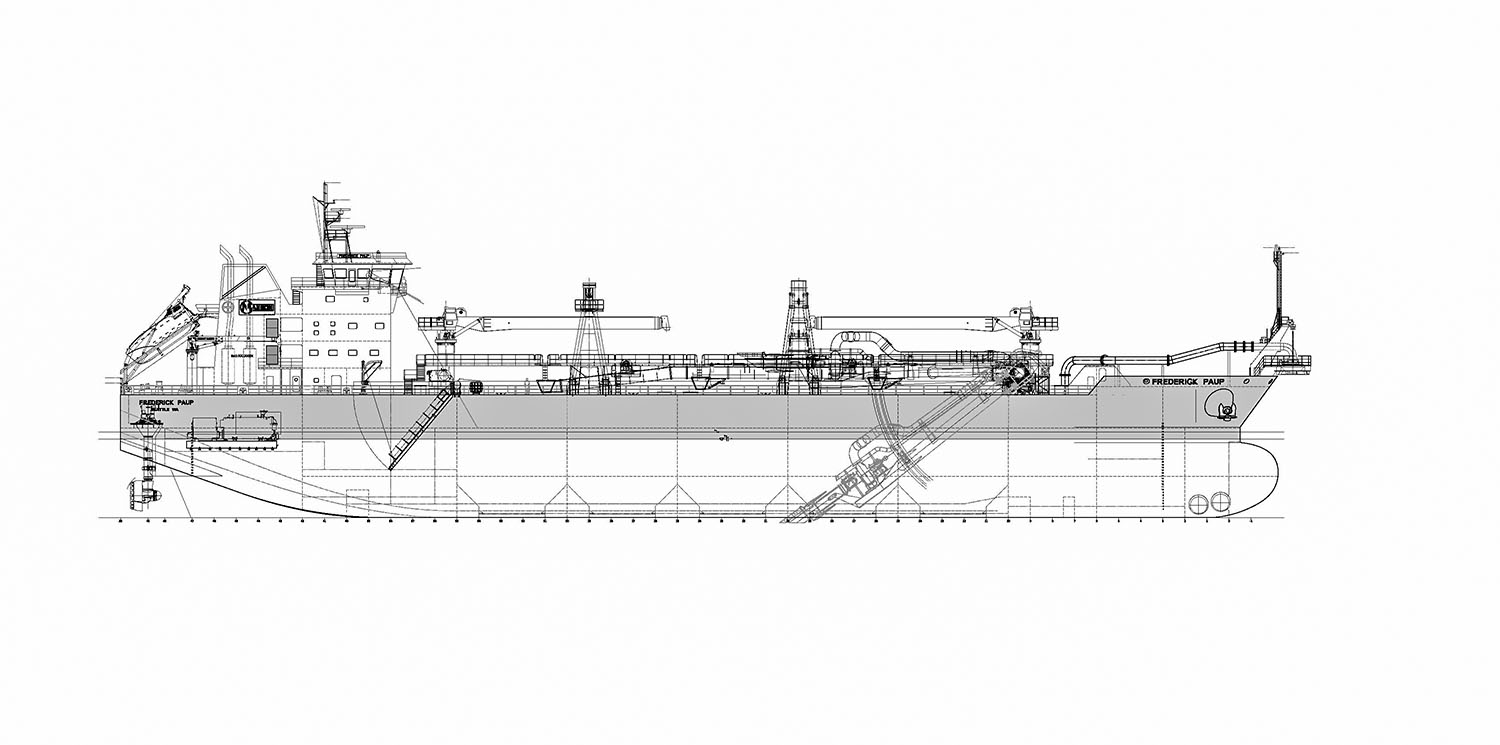

New construction dredge projects announced in 2020 include a 6,500-cubic-yard-capacity trailing suction hopper dredge to be built for Great Lakes Dredge & Dock at Conrad Industries’ Amelia, La., yard; a 27-inch cutter suction dredge for Mike Hooks from Mobile Pulley Works; a massive 15,000-cubic-yard-capacity hopper dredge for Manson Construction from Keppel AmFELS in Brownsville, Texas; an 8,500-cubic-yard-capacity hopper dredge from Eastern Shipbuilding Group for Weeks Marine; and a 28-inch cutterhead dredge for Callan Marine to be built at Hallmark Shipyard in Morgan City, La.

“Since the newbuilds represent investments across the board on dredge types—hopper, cutters and clams—it is really almost a complete overhaul of the U.S. fleet, with hopper capacity dramatically increasing, cutter horsepower dramatically increasing and clamshell dredge capacity and capability dramatically increasing,” Hanson said. “There has never been as much capacity and capability as there is currently in the U.S. fleet, and as I mentioned before, there is much more under construction.”

Richard Balzano, the new CEO and executive director of the Dredging Contractors of America, said that, with the dredging industry and government agencies working in partnership, the nation as a whole is the beneficiary.

“Capacity, funding and project approval: if any one of them is absent, then a project cannot get done,” Balzano said. “It is that simple. When federal and state governments and private sectors come together and invest in our ports and waterways, our economy expands and grows.

“The dredging industry investment in new equipment requires long-term commitments and significant capital,” he added. “Having project approval and funding lines established make those investments possible.”

Coronavirus Shadow

Of course, all the work in 2020 has fallen under the long shadow cast by the coronavirus. Early on, the dredging industry—as with the broader maritime industry—was recognized as an essential service, meaning work continued despite various state and local restrictions. Through all the impediments, dredge crew members remained focused, while maintaining safe work environments.

“Since we were initially named by CISA as an essential industry, the Corps really showed tremendous leadership by keeping their projects not only operations, but also continuing to bid their annual program,” Hanson said. “I don’t think folks realize just how important this was to the whole supply chain.

“We are fond of saying that shelter-in-place would not have worked so well if grocery stores and gas stations were not well-stocked, and that only happened as a result of the supply chain continuing to function,” he continued. “We learned a lot about collaboration through our industry groups like AWO and AAPA and others and federal agencies like MarAd jumping into the discussion.

“We also learned a lot about how to protect our workers better and took on a very disciplined and aggressive approach to making sure our crews and employees were counseled and protected.

“We credit our pre-existing safety culture for the discipline and trust that were required in this trying time and also want to give credit to Seafarers International Union and Operating Engineers for their cooperation as well.”

Balzano said those on-vessel measures ranged from ingress and egress protocols to utilizing personal protective equipment.

“We helped pass the word with successful operational modifications and techniques like ‘up-gangway’ procedures, which allowed the ships and the industry to effectively create a bubble protected from the outside world, so that we could keep operating,” Balzano said. “Keeping crews isolated and onboard the vessels was difficult, but it allowed us to keep operating, which was critical to keeping our economy moving. We worked with FEMA to get PPE out to field, and we monitored everyday conditions, all of which led to the successful operations to date.

“All this has come at considerable expense to the companies and considerable commitment from the men and women working extended rotations with significant restrictions,” he said.

In addition to the pandemic was the busy hurricane season, which together made 2020 a year-long logistical challenge, not just for dredgers, but for the wider maritime industry. Still, crews soldiered on, allowing for minimal interruption to ship channel traffic along the Gulf Coast.

Caption for photo: Drawing of the dredge Frederick Paup, which is under construction at Keppel AmFELS for Manson Construction Company.