Leading international brake supplier Dellner Brakes announced that it will be launching its brand new range of “plug and play” electrohydraulic braking systems to the U.S. market at this year’s International Workboat Show in New Orleans November 28-30 at booth No. 817.

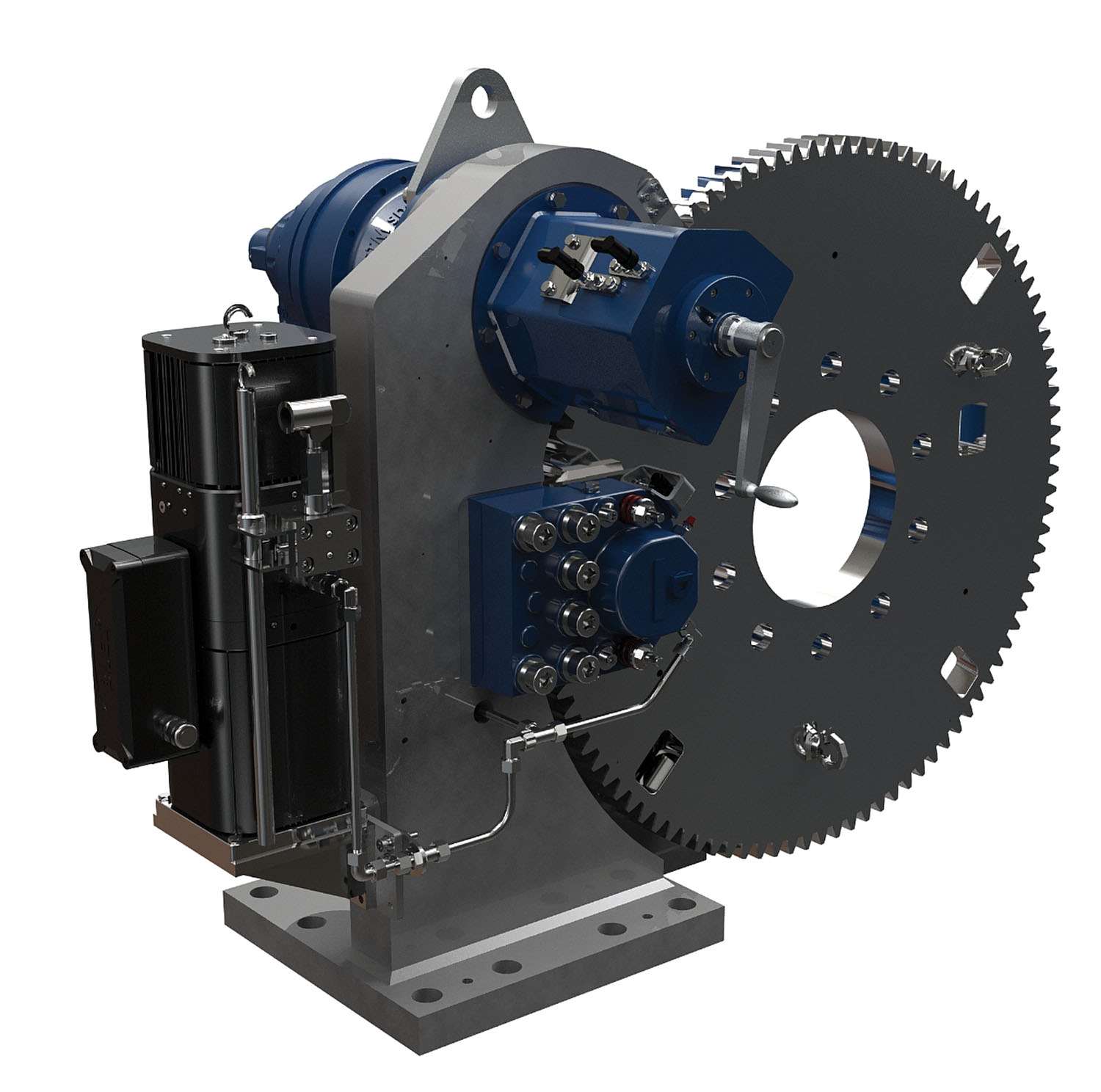

Combining the engineering of Dellner Brakes and sister company, Pintsch Bubenzer, the new BUEL STL system provides a compact, self-contained solution for stopping, turning and locking propeller shafts on vessels of all sizes, as well as for industrial applications.

As the name suggests, the system combines elements from Dellner Brakes’ innovative stopping, turning and locking (STL) systems with Pintsch Bubenzer’s patented BUEL electrohydraulic thruster and power package. Needing no external piping, the system is compact, easy to install and, with the BUEL using only half a liter of high-performance synthetic oil (compared to as much as 30 liters of hydraulic oil in standard hydraulic power units), are cheaper to run and environmentally-friendly.

“The new BUEL STL is the perfect solution for customers looking for a high performance, self-contained braking system that’s simple to fit and operate,” said Dellner Brakes CEO Marcus Aberg. “We are very much looking forward to showcasing this exciting new product at the Workboat Show, as part of our full portfolio of brakes and clutches for the marine industry.”

The new system combines a Pintsch Bubenzer BUEL Model G, delivering up to 240 bar of pressure, with a powerful Dellner disc brake offering stopping force of up to 517 kN. per unit. Customers can then choose to add a Dellner locking device that, available with hydraulic, electric or manual power, can deliver locking force of up to 1,300 kN. Customers requiring a full STL system can then also add a Dellner electrical continuous turning device, which uses an electric gear wheel to move the brake disc and attached shaft to any position—forwards and backwards—or turn the disc continuously, all with variable speed and turning force of up to 157 kN. A system with the above configuration and a 2.25-meter-diameter brake disc will provide 550 kNm. stopping torque, 1,450 kNm. locking torque and 155 kNm continuous turning torque (intermittent breakaway 233 kNm.).

The stopping, turning and locking functions can be operated individually or as a fully automated system. There is also a wide range of options for the system interface, from manual hand operation to electronic control panels and even remote wireless operation through a smart phone or tablet or whatever the customer needs.

Dellner Brakes’ STL systems fit around the ship propeller shaft to enable faster directional changes with maximum maneuverability. They also help lower fuel consumption, reduce load on propulsion systems and make routine maintenance quicker, easier and safer. Securing the propeller prevents damage to the shaft and bearings if the vessel is drifting or buffeted by waves.

It also allows ROVs and divers to operate around the propeller blades in safety. When in harbor, using the turning function to rotate the propeller can also help to reduce marine growth on the blades and lubricated shaft bearings.

Caption for photo: The BUEL STL braking system provides a compact, self-contained solution for stopping, turning and locking propeller shafts on vessels of all sizes. (Photo courtesy of Dellner Brakes)