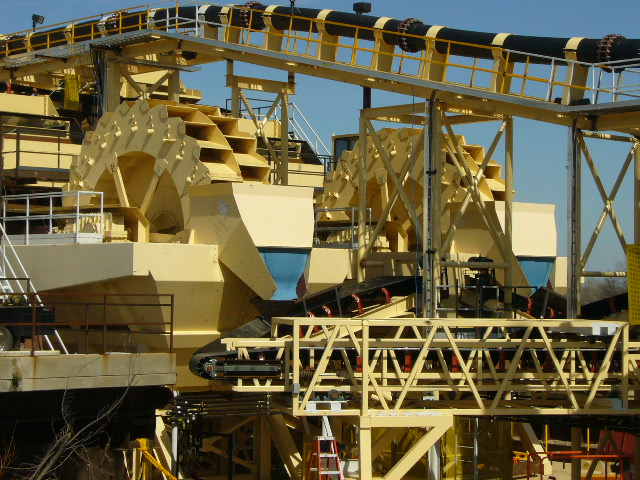

DSC Dredge, LLC and Stichweh, LLC have entered into a manufacturer’s cooperation agreement to promote each other’s products. The main product of SMT-Stichweh is washing and dewatering bucket wheels, which is a product DSC began including as an option with its dredges. DSC Dredge works with customers to determine the best dewatering wheel for their project requirements and conditions.

The dewatering wheel allows for development of different grades of sand through the adjustment of a single setting on the bucket wheel controller. This enables the dredge to meet the material conditions and optimize production. The bucket wheel rotates with 0.5 – 2 rpm, requiring low power consumption and causing little wear. Five production series are available for the different material conditions and requirements from gravel dewatering to fine sand washing, finest sand classification, multiple wheel product classification and finest sand recovery.

Andrew Snoby, vice president of Stichweh, described the dewatering bucket wheel design saying, “Coarse-grained material can be cleaned and dewatered in a bucket wheel with or without screens. For fine-grained material like sand or grain mixtures special washing, dewatering and recovery systems are necessary. Stichweh has washing and dewatering bucket wheels designed for these fine-grained materials applications.”